VW Baywindow Bus - Engine Oils w/ Zinc

by Richard Atwell

(c) Copyright 2020-2021

VW Baywindow Bus - Engine Oils w/ Zincby Richard Atwell |

|

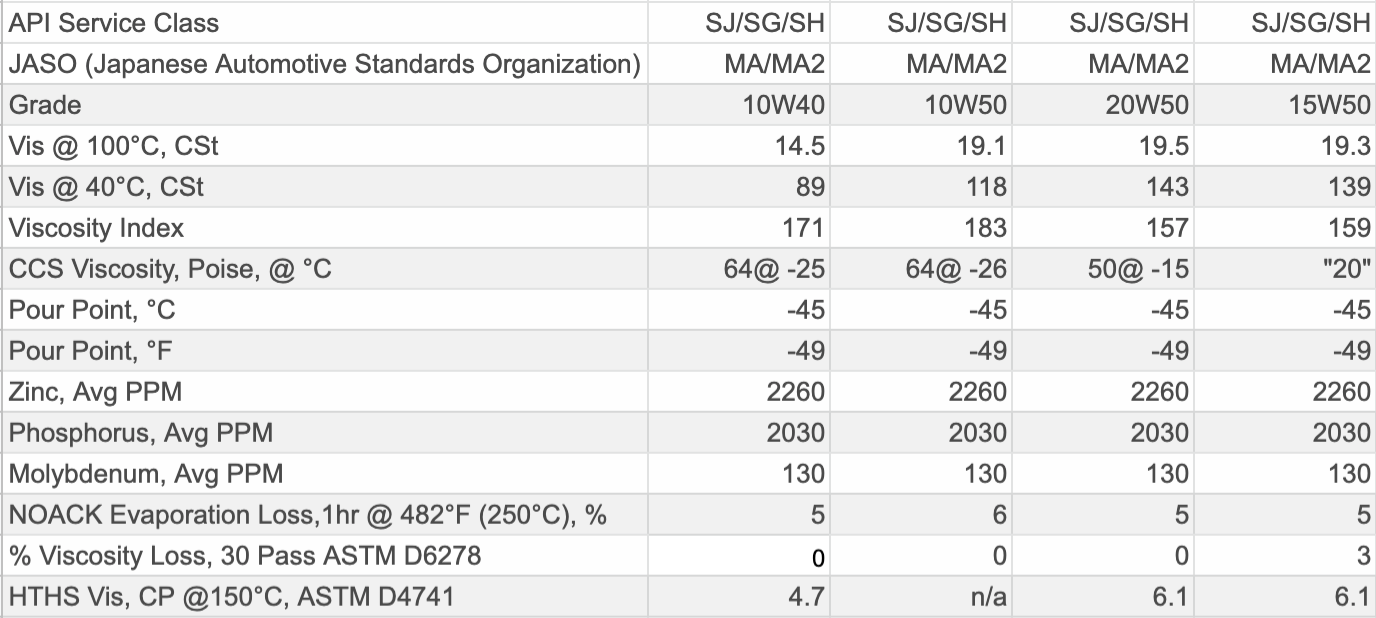

Full Synthetics with SH levels of Zinc (2020 data):

Companion Articles:

Modern engine oils contain additives to maximize its lifespan while helping to protect metal surfaces:

Protective additives:

Performance additives:

Surface protection additives:

Aside from the development of synthetics, advancements in oil engineering have come from the chemistries of the additive packages that are incorporated into modern engine oils and improve with every generation.

One of the most effective anti-wear agents developed is ZDDP (Zinc dialkyldithiophosphates), or sometimes ZDP. Although originally engineered as corrosion inhibitor in the 1940's, it has been proven effective as an anti-wear agent where it coats the load bearing surfaces inside your engine.

The active ingredients in ZDDP are Zinc (Zn) and Phosphorous (P) compounds which bond to metal oxides (metallic engine surfaces) to act as a sacrificial layer between any two metal surfaces.

In the event that they make contact because the film of oil is insufficient they will act as a heat activated surface protectant. Only a tiny amount (e.g. 0.08% or 800 ppm) is required for the compound to be effective.

Sometimes ZDTP is specified (Zinc dithiophosphate) but I'll simply refer to these Zinc compounds as ZDDP from here on.

Watch this video to learn more about additives:

Since 1997, newer API ratings have come with reduced ZDDP levels in an effort to reduce pollution. As oil consumption increases, the amount of organic Phosphorus present in the exhaust increases and the 3-way catalytic (CAT) converter becomes coated by it; its lifespan and therefore effectiveness is reduced. This leads to increased emissions which are regulated by U.S. EPA and other bodies.

Here's an old chart from the early 2000's tracking the decrease in P/Zn content:

So, why the concern? In high wear areas such as where the camshaft lobes push against the lifters there have been recorded failures attributed to the change in ZDDP levels.

The high performance community with their high lift cams first raised the alarm bells on this issue. They first noticed that scuffing started to appears on the lobes of the camshaft after the ZDDP levels dropped (starting with the API SJ rated oils and becoming more apparent with the SM rated oils).

While some manufacturers substitute other compounds as anti-wear and extreme pressure agents (Boron for example), some brands just reduce the ZDDP level outright in order to meet the mandated maximums in the API specifiations.

When asked about their ZDDP levels, Liqui-Moly replied to one of my emails for example and said that Zinc levels aren't the most important factor when judging the anti-wear capabilities of an engine oil. I believe this to be true but as they don't ofter specific testing data to the public, verifying the P/Zn levels is the really only guideline for classic car owners based on past experience and the long history of ZDDP use.

What can generally be concluded about ZDDP levels in 2020 is that:

These questions now come to mind:

So let's try to figure out a way through all of this...

The VW air-cooled engine is a push-rod boxer design using flat tappets. The tappet faces are not actually flat but slightly crowned (convex) in profile. They ride on the camshaft lobes which are profiled in such a way as to promote rotation of the lifters in their offset bores. We only say flat tappets to distinguish them from "roller lifters" which have a actual rotating wheel at one end of the tappet.

Here's a nice video of a Type 1 engine is motion (crankshaft in red and camshaft and lifters in yellow below):

Historical point: the VW Type 1 air-cooled engine was engineered in the 1930's when motor oils had no ZDDP at all. The Type 4 engine was engineered in the early 1960's with 800 ppm levels. We can assume the manufacturing processes used for both engine were standardized at some point using the same raw metals and hardening process.

The later oil formulations specified in the owners's manuals (SD, SE, SF, SG) have levels of ZDDP that are at least 1000 ppm and millions of miles have been driven on those oils. On this basis alone, it's fair to say that factory stock air-cooled engine maybe dependent on SE or higher levels of ZDDP.

As classic VW owners, we simply don't know what the absolute minimum P/Zn level should be for a air-cooled engine because there are no specs from Volkswagen other than the preset ZDDP levels that were present in SB through SE oils.

We do know that for engines under high temperature and high stress, panic within the high performance community started when the SJ classification appeared and the virgin oil analysis (VOA) readings came back and verified lowered ZDDP levels. By the time that the SM classification came into effect in 2005 and the SM oils underwent VOA, the panic was in full swing.

We can guess that the ZDDP level should be at least 1000 ppm for a stock air-cooled vw engine (SE) but we can't easily verify it without trying to destroy a few camshafts in the process.

Due to ever changing formulas, VW and other manufacturers now rely on their own numbering schemes like VW 502.00 to help identify engine and gear oils that meet their own engine standards. If you have such a modern vehicle, the owner's manual requires you to use an oil with that designation only.

Going forward: while verifying P/Zn levels will always be possible through an oil sample analysis, proving the minimum level of anti-wear protection in the secret proprietary formula of each new generation of oil will remain cost prohibitive and out of the reach of just about everyone except the oil companies themselves. This leaves those of us with classic cars reaching for the formulas marketed for classic cars with "Increased zinc levels for extra engine wear protection" for years to come...

It is generally accepted in the VW community (or any other classic car community out there) that if you want to maximize camshaft life, you should ensure that your oil has a higher level of ZDDP than the average bottle of API SN oil. This is not lab proven: it is collective wisdom.

API classifications do NOT indicate the exact amount of P/Zn in your bottle of oil: they only specify to maximum allowable levels which is often too little for comfort.

Fortunately for classic vehicles, some grades of oil are exempted from the low ZDDP level requirements regulated by API and EPA because they constitute a small percentage of the overall usage:

The American Petroleum Institute (API) and International Lubricants Standards Approval Committee (ILSAC) have mandated the reduction of phosphorus to extend catalytic converter life. However, reducing the level of ZDDP can compromise protection to engine components, most notably in flat tappet camshafts. Current API SN and ILSAC GF-5 specifications for gasoline engines have maximum and minimum phosphorus levels of 800 ppm and 600 ppm, respectively, for SAE 0W-20, SAE 5W-20, SAE 0W-30, SAE 5W-30 and SAE 10W-30 motor oils. - source AMSOIL

To further complicate things, just because a SN, SN Plus or SP is displayed inside the "API donut" on the back of the bottle, it doesn't mean that the bottle of oil is too low in ZDDP for your engine either. How's that for confusing!

As any excluded oil may or may not have more than the minimum level of ZDDP specified by API. the only way to confirm that the desired level of ZDDP is present, with the SP oil rating in effect as of late 2020, is to download the product data sheets for the oil you intend to use. If the published data sheets don't say, contact the oil company directly and ask for the levels. If they won't say, shop for another brand of oil that you can verify.

ZDDP level is one distinction between brands that allows for relative comparison and car owners often send off oil samples for analysis (virgin or used) then share the results online in forums like the one below to help other enthusiasts locate brands that are more suitable than others:

Visit the Bob is the Oil Guy Forums (especially if you want to go down a giant oily rabbit hole).

Since there has been no desire to mandate the printing of the ZDDP level in product sheets or on the containers, you must look it up yourself.

This is the big question that needs to be answered and in searching for my own answers, it has lead me to these opinions...

In Dec 2007, Bob Olree (GM's Powertrain Fuels and Lubricants Group) wrote an "Engine Oil Myths" titled article for GM Techlink which has been WIDELY quoted on the internet. I've archived the entire article in the references and he wrote:

"The latest myth promoted by the antique and collector car press says that new Starburst/API SM engine oils (called Starburst for the shape of the symbol on the container) are bad for older engines because the amount of anti-wear additive in them has been reduced. The anti-wear additive being discussed is zinc dithiophosphate (ZDP)."

"Those who hold onto the myth are ignoring the fact that the new Starburst oils (SM -ed) contain about the same percentage of ZDP as the oils that solved the camshaft scuffing and wear issues back in the 1950s. (True, they do contain less ZDP than the oils that solved the oil thickening issues in the 1960s, but that's because they now contain high levels of ashless antioxidants not commercially available in the 1960s.)"

Is he right? Bob co-authored the ASTM RESEARCH REPORT titled, "Development of the Sequence IIIG Engine Oil Test" which in part measures an engine oil's high temperature wear performance as it pertains to severe cam & lifter wear. He's no doubt a smart and well educated guy.

For the bulk of enthusiasts who love their vehicles nor have they experienced a camshaft failure but fear it, his position has largely fallen on dear ears much to the delight of the oil pour-in additive industry.

Here's one counter-argument to Mr. Olree's article from 2008:

ZDDPlus Tech Brief #2 - ZDDP and Cam Wear: Just Another Engine Oil Myth?

Now, given that...

...all of which sounds compelling especially if you've already decided that ZDDP is important but what are we to conclude from all these opinions?

All of that info above dates from the SM oil wars. In searching for an update, I came across this Feb 2018 article by John Martin, titled "Let's Talk Engine Oils":

Even OEM engineers, such as the late Bob Olree of GM, realized that insufficient phosphorus is present in SN oils to protect engines with high lift cams and stiffer valve springs. He, like many others, recommends that we use at least API CJ or CK-4 diesel oils in these engines.

So, as we've stated before, the safest thing for engine builders to recommend is for their customers to use API CJ-4 or CK-4 diesel oils in mildly modified engines and hot rod oils with increased ZDP levels in engines with flat tappets and very stiff valve springs. Hot rod oils have twice as much ZDP as diesel oils, and the ZDP levels in diesel oils will probably decrease over time. You'll be protecting your valve train parts much better with these oils.

So one conclusion you could draw, is that the problem was REAL but doubted as the exact minimum level of ZDDP couldn't be determined. This primarily affected engines with very high valve spring pressures. Do air-cooled VW's count? If you have a high performance engine, probably. If you have a stock engine Type 1, probably not.

And what are the CJ-4 and CK-4 levels for ZDDP? Arg!

A multitude of Type 4 camshafts were used in several VW/Porsche models:

One thing they all have in common is that the wear on the camshaft lobes at the end of their service life displays a signature wear pattern.

Photo courtesy of Ray Greenwood |

In the 4-cylinder horizontally opposed "boxer" engine, the cams are shared between the cylinder banks and the symmetry of the wear pattern clearly depicts the offsets of the lifter bores. It also depicts that despite the width of the intake cam (32mm) and the diameter of the lifters (Ø 24mm), the greatest wear occurs in the middle. First, the face of the convex lifters wear flat then concave which then carves out the cam. I suspect the exact mileage that this happens, depends on how often you change your oil and what kind of oil you use.

The brown marks are oil stains where the wear is actually the least. The groove in the center of the cam is where the center of the lifter is wearing down against the cam and the sharp edge is where the lifter has actually become slightly concave and is carving out the cam.

It is sometimes claimed that the 1978-1983.5 valve train with its steel push rods and hydraulic lifters is to be faulted for the worst of these wear patterns. While the hydraulic lifters are designed to cushion the action of the valve train, until they are pumped up the lifter may "float" between the camshaft lobe and the pushrod tip held only in place by the weak plunger spring within the lifter.

However, the forces exerted come via the valve springs which are slightly "heavier" than the ones used with solid lifters and this contributes towards the increased level of camshaft wear over the life of the engine.

Regardless, Type 4 camshaft wear is a Day 1 design issue that may have more to do with the level of anti-wear additives present in the oil than anything else.

When I researched the ZDDP levels that were set by API, I discovered the levels have varied substantially over the years. I've documented this at the end of Part 1.

The 1970's SE rated oils maxed out around 1000 ppm and the SF oils were reformulated to improve upon the anti-wear properties to reduce camshaft scuffing. Now, the average bottle of -40 or -50 weighted engine oil is BELOW the SE levels (650 to 800 ppm) of the factory production period. Consider that the Type 4 engine was designed when only SD oils were available which had even lower levels of ZDDP.

One of the goals of this series of articles is to raise awareness of the old claim that "oil is oil" just isn't the case anymore: each brand and grade have varying levels of extreme pressure and anti-wear agents in their additive packages.

With regard to Type 4 camshafts, there were no Type 4 specific oil requirements as per VW. However, the design is clearly wear prone and on this basis, every Type 4 engine should be using a engine oil with a higher level of ZDDP (>= 1200 ppm) for additional protection of the camshaft and for longer engine life.

As of 2020 with API SP oils, we've reached the 650-800 ppm level of ZDDP with no opinion or test results or the advice from the community. No news is good news, right?

How much ZDDP is too little is the $64,000 question especially since oil companies are substituting other compounds for some of the ZDDP. Given that the amount of ZDDP is still at least 650 ppm, it implies that it's still the best compound for the task doesn't it?

What has become particularly worrisome of late is that for the first time, the API testing regimen for a SP rated oil does NOT include laboratory testing that verifies "backward compatibility"" according to some reports.

In July 2019, Driven Racing Oil wrote:

If you have a flat tappet cam engine, take note of this statement regarding the new API SP / ILSAC GF-6 oil specification:

"The industry has not confirmed back-serviceability for oils tested in the Sequence IVB, and further testing may not be conclusive."

Here's what's taken place with regard to API SP testing methodology...

Engine Tests: ILSAC GF-6 is the first standard to incorporate seven new tests. Five of which are replacements, two are entirely new and one test is carried over from GF-5. There is a total of eight engine tests catered to modern cars, including those with turbochargers. Click on the graphic to learn more.

Previously, there was a test that determined how well an oil performed to prevent cam and lifter wear that was relevant for air-cooled VW engines:

Sequence IIIG Test: evaluate automotive engine oils for certain high-temperature performance characteristics, including oil thickening, varnish deposition, oil consumption, and engine wear.

Text Fixture: 1996 General Motors Powertrain 3800 Series II [no longer in production], water-cooled, overhead valve (OHV) 4 cycle, V-6 engine and uses a single camshaft operating both intake and exhaust valves via pushrods and hydraulic valve lifters in a sliding-follower arrangement.

Latest ASTM Tests for SP oils:

Sequence IIIH (replaces IIIG): The objective of this test is to measure lubricant thickening, oil consumption and piston deposits under high-temperature conditions. It was developed to simulate high-speed engine operation under relatively high ambient conditions.

Text Fixture: The engine used is a 2014 Chrysler 3.6L V-6 Pentastar fuel-injected DOHC 24-valve gasoline engine

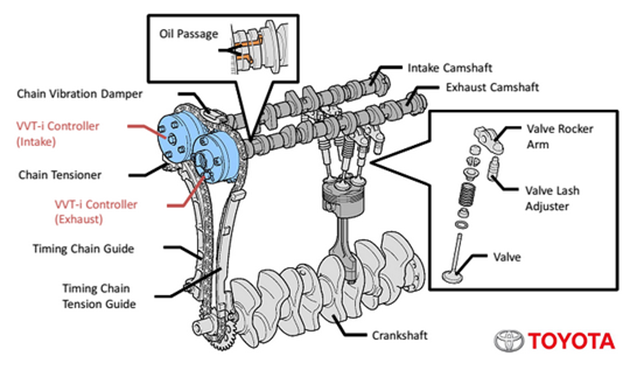

Sequence IVB (replaces IVA): The objective of this test is to evaluate the effect of an automotive lubricant on tappet wear for engines using direct-acting overhead cam-valve trains.

Text Fixture: A Toyota 2NRFE 1.5L fuel-injected, inline four-cylinder engine with dual overhead cam shafts and four valves per cylinder is used.

As you can see, these test engines have neither push rods nor flat tappers. Instead they are equipped with modern style rocker arms with integrated rollers that have little in common with air-cooled VW engines.

To date, I find this to be the most compelling argument requiring VW owners to scrutinize each bottle of engine oil because standards are changing and our air-cooled VWs are truly classic cars and slowly becoming antiques.

Give that...

...we should probably be using specific engine oil formulas that were designed for and have passed the Sequence IIG tests rather than on the average off-the-shelf bottle of oil.

What has largely been lost through internet discussions (the so-called on-line oil wars) according to one author (Michael Grant see References) is the nature of the original problem:

There have been increasing numbers of cam/tappet failures, especially in the last four or five years. The Engine Rebuilders Association (AERA) has been keeping records for the last ten years. In that period, there have been more reported cam/tappet failures, with the largest jump in numbers of failures after 2004. Of the failures reported, 25% were traced to poor break-in procedures. The other 75% were traced to use of modern oil for the break-in.

So if your air-cooled engine has been properly broken in with sufficient levels of ZDDP in the assembly lube along with a special purpose break-in oil, why worry?

If you have just uncrated your engine, you need to add 3.5L of the oil recommended by your engine builder. If the recommended oil is low in ZDDP, should you upgrade to one with a higher level of ZDDP? If there is no recommendation, then again switch to an oil with high level of ZDDP? Most times, the assembly lube is ZDDP rich and quickly disperses into the oil sump assuming they used such a lube.

Here's a YouTube video of a Type 1 engine last rebuilt in 1996 that ran for 20 years and finally suffered a destroyed camshaft lobe without attributing the exact cause. This is only to demonstrate what they look like in extreme wear cases and we know nothing about how the engine was used or what oils were used.

Let's enumerate the conditions that necessitate rebuilding of the VW air-cooled engines:

Only severe campshaft lobe wear has been attributed to low ZDDP levels. It's only one of several engine issues and NOT the most common for VWs. Further, within the VW community we did not experience widespread cases of failure largely because the value spring pressure on the stock engine is much lower than a hotrod engine and also lower than the pressure exhibited by the laboratory test engines used to test engine oils.

When the engine is in tune, it is the function of the cooling system to remove heat from the engine so that it operates within the "green zone". The oil lubricates and removes heat from the rotating parts and the oil is cooled by the air-cooled oil cooler. When the engine is out of tune or out of spec, it's under stress and as the oil temperatures elevate, wear eventually increases.

To maximize engine life, accelerate the standard maintenance schedule so the oil carries a reasonable (design) load and runs as cool as possible.

Refresh:

Log book:

Good Habits:

If you Google Albert Klein 1963 Beetle you'll discover that Albert eventually put 1,610,000 miles (yes 1.6 million) on his VW bug. After 24 years, he'd gone through 7 engines, 3 transmissions and 150 tires including 300,000 miles on a single crankshaft.

What was his secret? Oil changes every 1,500 miles, valve adjustments every 4,000 miles. He also preferred using an oil temperatures gauge, oil pressure gauge and he modified his Type 1 engine to use an external oil cooler and oil filter. Good habits and good maintenance:

This is my favorite YouTube video that show's how a little TLC goes a long way towards keeping the engine power close to factory spec:

If you increase the level of Zn by too much it's been said that the spark plugs can foul but I'm not sure this is accurate because motorcycle oils have a lot of ZDDP in their additive package and I haven't noticed fouling with my bike. You are unlikely to find automobile engine oils with such high levels as motorcycle oils.

As ZDDP is available on the shelf as a pour-in-additive there is potential for abuse but from what I've read it's more about upsetting the balance of the additive package than anything else. Watch:

I personally would think twice about pouring a bottle of ZDDP additive into your crankcase and try to out engineers the oil chemists. Also consider reports that claim that the load bearing capability of the oil can actually be REDUCED by a pour-in-bottle of ZDDP. This is counter-intuitive but apparently it is because the highly engineered and balanced formulation has been upset.

Finally, if you are thinking of buying a $2 bottle of oil from the dollar store watch this (YouTube) or watch this video from PQIA.org (YouTube) that warns that with or without the API rating you are rolling the dice at this end of the price scale. With reputable brands, you really only have to be concerned whether or not the ZDDP levels is the minimum or boosted.

Engine wear is inevitable, sadly. The question is what can be done using the ever-narrowing selection of engine oils to extend the lifespan of the engine and put off the rebuild? ZDDP seems to be a key additive known to provide the necessary boundary lubrication when oil shears under the stresses within the engine.

Is more ZDDP better? Up to a limit. Is 800 ppm too little? Maybe. Is 650 ppm going to lead to damage later on? Only testing can prove this. Have the marketing folks got the better of us? Will more frequent oil changes avoid the entire ZDDP debate?

Whichever side of this debate that you side with, there is no harm selecting a SN rated oil with higher (SH) levels of ZDDP to use in a classic VW engine.

My advice is to err on the side of caution and go with a known high level of ZDDP in the oil. You'll only be offending the tribologists who engineer motor oil.

When you consider that they literally mix base oils with liquid additives provided by other companies and then have 3rd parties run the oil in test engines, we really need them to state unequivocally that they've run the oil in a flat tappet engine and that the results were positive. We know that as time goes on the number of tests will be limited to more modern engine designs because it's cost prohibitive for them to keep expanding the number of test engines for which OEM replacement parts cease to remain available.

To me this choice requires a pragmatic approach that is cost-effective: shopping around for the best value synthetic oil; no need to worry about pour-in additives or expensive boutique oils or racing oils, just yet.

While I'm sure there are situations that warrant speciality oils, for the average daily driver you'll be unaffected by your choice assuming the P/Zn levels are >= 1200 ppm and ensuring that the oil grade is appropriate for your climate. It will also be useful to seek out oils with SL, SM, SN certification while they are still available.

What's digging at the back of my mind on this issue is this: it takes the VW engine several seconds to build full oil pressure and 80% of engine wear takes place at startup. Therefore, isn't this fact directly related to the levels of anti-wear additives present in the oil that have previously bonded to the load bearing surfaces?

I would conclude that when you are trying to ascertain the specific ZDDP level for your vehicle you are largely buying into an insurance policy for "added wear protection" with the key word being added.

My advice is to seek out the well stocked oils with "increased levels of Zinc". In my experience, they are not so hard to locate and when on sale, you are often paying less than you would for a spec oil with far less ZDDP.

We now break for this gratuitous Mobil 1 commercial from 1990:

Backstory: The million-mile motor (theguardian.com)

Now is this the best oil ever made or the best BMW ever made? How much ZDDP was in the engine oil? We'll never know.

If you search for the specs on the SH rated oils of the past, you'll discover that the levels were much higher across the all brands: just google for archived virgin oil analyses or visit Bob Is The Oil Guy VOA Forum.

Here's the Mobil 1 Product Data Sheet (2019) which lists all the P/Zn levels for the Mobil 1 product line. I've picked out the formulas that exceed Zn levels of 1100 ppm and you'll notice the rest have ZDDP levels that are SN limited (generally 800/900 but some as low as 650/750 which is nearly half as much as desired).

If you purchase an engine oil with a SN, SN Plus or SP API rating, it will likely have minimal levels of ZDDP.

This is why Mobil 1 is a good brand: there is a synthetic grade for each climate with published ZDDP levels suitable for aircooled VW engines at price point (thanks to Walmart) that I believe is a best value.

The ZDDP levels have also remained stable since 2008 (as far back as I can check) for these formulas which you can't say about many other brands.

| Label | API | Viscosity | P (ppm) | Zn (ppm) | VI | TBN | Mobil Formulation | Best Price |

|---|---|---|---|---|---|---|---|---|

| Mobil 1 FS | SN | 0W-40 | 1000 | 1100 | 185 | 12.6 | European vehicles High Temp/Stress | Costco 6 pack |

| Mobil 1 Turbo Diesel Truck | SN | 5W-40 | 1100 | 1300 | 153 | Diesel Trucks | Walmart 4 qt. | |

| Mobil 1 Formula M | SN | 5W-40 | 1000 | 1100 | 168 | 8.0 | Mercedes | Summit Racing 6 pack |

| Mobil 1 Racing 4T | SN | 10W-40 | 1200 | 1300 | 159 | All motorcycles | Walmart 1 qt. | |

| Mobil 1 FS X2 | SN | 5W-50 | 1000 | 1100 | 179 | 12.6 | Porsche High Temp/Stress | Summit Racing 6 pack |

| Mobil 1 | SN | 15W-50 | 1200 | 1300 | 160 | flat tappet engines | Walmart 5 qt. | |

| Mobil 1 V-Twin | SJ | 20W-50 | 1600 | 1750 | 142 | All motorcycles, especially V-Twin | Summit Racing 6 pack |

I don't recommend using 0W-40 in your vw air-cooled engine although I have no experience with or have tried it with solid or hydraulic lifters. As 5W-40 is already good down to -30ºC as per VW specs, we have to assume that the bearing clearances in a 1960's engine design (Type 4) were never intended to operate using a 0W-40 grade of oil. Further, I've read about dealership mechanics switching from 0W-40 to 5W-40 with newer models cars with the explicit goal of quieting the mechanical engine noise reported by the driver. This suggest that the oil's load bearing capability is somewhat compromised by its ability to flow at cold temperatures but this is not a scientific assessment by any means.

These grades are generally suitable for an aircooled VW engine, depending on your climate and they all vary by price and availability. Diesel specific oils with an additional gasoline service rating can be used in gasoline engines. In fact, Diesel grades were the go-to engine oils when the ZDDP levels dropped because at the time they generally had higher levels of ZDDP compared to gasoline engine oil grades. Many still do.

It's easy to see that Mobil 1 15W-50 although SN rated (Red Label) has API SH (1996) levels of P/Zn (1200/1300 ppm) and is specifically intended for flat tappet applications like classic VWs and many other classic vehicles. You get the best of all worlds: synthetic, enough ZDDP, modern SN additive package. Mobil 1 5W-50 has slightly lower levels but still higher than the average SN rated oil.

What grade you should use, depends on your climate: I ran 15W-50 year round when I lived in California. While the highway speed limit was 65mph (105 km/h), traffic moved at 75mph (120 km/h) or faster. With an outside temperature of 30ºC and the engine running loudly at 3500-4000rpm+ you want a good quality oil ending in -40 or -50 that can remove the heat from the aircooled engine.

Latest info on packaging: I do not know what the P/Zn levels are in the most recent API SP Black labeled 5qt. jug but you will notice that the barcodes are identical. When I hear back from Mobil 1 (Exxon) on the P/Zn levels, I will update this page...so far Exxon tech support is waiting for their marketing team to sort out the labelling differences. So far their website lists all the grades that meet SP performance standard which are exclusive of the table above.

On the back of the bottle (Red label) it is written:

Mobil 1 15W-50 contains extra anti-wear protection (Zinc) for high performance engines.

Mobil 1 is the brand of engine oil I've used most-often since 2003 and I'll continue to use it:

Sometimes the specific grade you need is not commonly found on auto parts store shelves (just like a set of VW bus brake shoes or many other VW parts) which often requires me to source it online; I usually purchase 5qt. jugs to save money.

The last time I purchased it from Walmart.com was in 2018 for $5.10/qt (Red label SN rated) by purchasing two 5qt jugs with free shipping.

The style of the container has changed over the years and will no doubt change again. Just be sure to check the labeling, API rating and P/Zn levels before purchasing.

Mobil 1 15W-50 "Super Syn" went off the market around 2004 and reappeared in 2007 after a large outcry from the air-cooled Porsche community.

At the time, Mobil 1's FAQ stated:

Q: Why are you reintroducing Mobil 1 15W-50? Have there been any changes to the formulation, or is it identical to the previous product?

A: Mobil 1 15W-50 is being reintroduced based on popular demand. Mobil 1 15W-50 provides higher viscosity, designed to provide extra protection for performance vehicles and vehicles that operate in severe service, such as towing, hauling and racing. Additionally, Mobil 1 15W-50 contains higher levels of anti-wear (ZDDP or Zinc DialkylDithioPhosphate) that may be required for certain racing applications and camshaft designs. This is a new Mobil 1 15W-50 formulation and is not the same as the product that was marketed a few years ago.

The older "Super Syn" formulation came in a plastic bottle with a red cap (API SM Barcode 58196 57351). It was replaced with a version with a gold cap that was labeled "Extended Performance which I still have a bottle of. It was also API SM rated and had the SAME barcode! but the formula was slightly different comparing Mobil 1's own specs. It went off the market around 2009-2010.

Now the cap is silver as seen above in the photos. This version has been around since at least 2011 although the API rating has changed from SM to SN to SN Plus and now to SP.

There are many many synthetic oils that fit in this category...Castrol is a good alternative to Mobil 1.

Castrol Edge is my second choice when I cannot source Mobil 1 in a specific grade at my desired price point. It's often on sale at 50% off for a 5L jug.

Sources:

Redline High Performance Oils have SH levels of ZDDP:

Zinc Content: 1350 ppm

Phosphorus Content: 1230 ppm

I have read that the 5W-40 Euro formula does not have these elevated levels of ZDDP, so be sure to contact Redline to get the specific levels for the grade you are interested in.

Redline motorcycle oils have even higher levels of ZDDP than automobile oils.

If you aren't concerned about the $$$ of oil and desire the highest levels of ZDDP and don't want to measure and mix additives (which I don't recommend), check out Redline Motorcycle/Powersports for motorcycles in the black bottle w/ silver label.

The P/Zn levels are nearly double the SH levels:

Some people argue that more ZDDP isn't better. Some experts even say that it is detrimental and causes corrosion. Some argue that it's not worth the cost. Some argue that motorcycle oils don't work in cars because they lack the friction modifiers. Some argue the opposite: that motor oils not designed for a motorcycle's wet clutch and transmission won't work. Only one way to find out...

I personally have NO experience with the long term effects/benefits of using motorcycle oils in a air-cooled VW engine but as a starting point I would be reading the spark plugs to see what effect it had (if any) and NOT using a catalytic converter who can become Phosphorus poisoned (California models, later Vanagons, etc).

All in all, while this option was an interesting prospect back in 2007 during the ZDDP scare, with multiple high ZDDP multi-grades currently available, there's really no need to experiment or pay the premium prices for motorcycle oil.

Z-ROD: "High zinc & phosphorous content for classic cars & street rods. Ideal for flat-tappet cams or roller cams. Robust anti-rust protection for extended storage."

Zinc Content: 1440 ppm

Phosphorus Content: 1320 ppm

AMSOIL TSB 2011: Flat Tappet and Camshaft Lobe Lubrication (PDF)

Background:

Testing:

The Debate:

Camshafts:

Other:

01/03/21 - Moved from OilSelection.html into separate article

01/05/21 - Added AMSOIL, updated Redline info and added valve train test background info

01/07/21 - Added test engine photos